NORDITUBE

Worldwide leading partner in pipe rehabilitation technologies. We provide a specialised methos for rehabilitating pressure for municipal and industrial applications.

ABOUT NORDITUBE

“One-stop shop” for innovative pipe rehabilitation

This creates a “one-stop shop” for innovative pipe rehabilitation solutions. Under the motto “all from one source”, NordiTube Technologies provides the entire range of pipe rehabilitation technologies, including materials, equipment, technical support and approved high-end lining material systems.

OUR PRODUCTS

NORDILINER

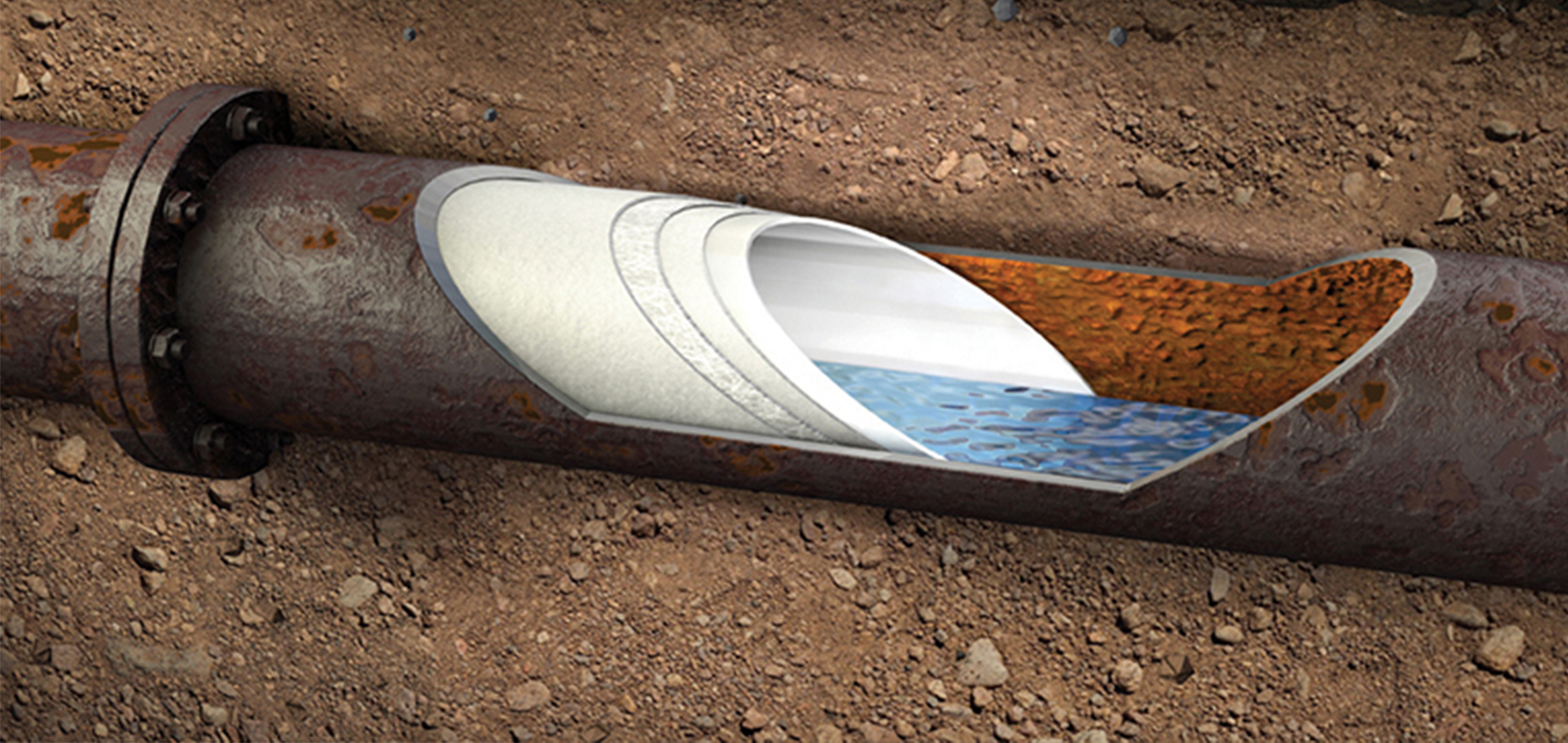

The NORDILINER is structurally self-supporting and therefore independent from the host pipe. The liner will remain completely stand-alone. Multiple application areas such as potable water, industry, gas, oil & pipes.

IH LINER NSF/ANSI 61 approvedThe strong and flexible liner is folded and pulled into the existing pipe. Special tapes help it keep its shape during installation. It´s then inflated with air or by fluid pressure, without bonding to the old pipe. Unlike CIPP, no curing is needed. Keeping drinking-water networks functional is elemental to maintaining our standard of living and is an important responsibility of water suppliers. Leaky pipelines result in wasted resources and can cause serious damage to infrastructure. No resin, no impregnation, no curing! |

|  |

NORDILOC XA trenchless PVC-U spiral lining system, installed under live flow with no excavation, offering durable, tight-fitting liners and long-term performance with minimal disruption. |

| NORDILOC SMade from pipe-grade PVC-U, is a durable pipe with no weak points that reduces installation and maintenance costs. Its smooth surface minimizes cleaning. |

|

|

|

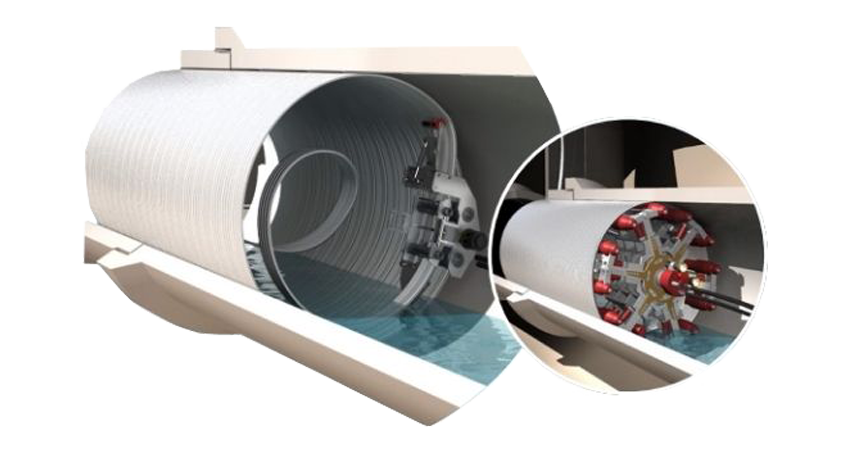

Product characteristics- In-situ Installation: By helically winding a PVC-U strip through existing access chambers, eliminating the need for excavation

- Adjustable Diameter: The machine begins small for easy entry, forming a spiral pipe that fits the host pipe.

- Flexible Navigation: The spiral design adapts to joints, bends, and local damage.

- Tight Fit Expansion: After winding, the spiral liner is expanded to tightly bond with the host pipe’s inner surface.

- Structural Renewal Without Digging: The result is a durable new PVC-U pipe that ensures long-term rehabilitation without excavation or major disruption.

|

| Product characteristics- Self-Cleaning Surface: Smooth and dirt-resistant, requires minimal cleaning and enhances flow efficiency.

- Improved Hydraulic Capacity: Often increases the hydraulic performance of rehabilitated pipelines.

- Groundwater Resistance & Consistent Material Properties: Mechanical installation is unaffected by groundwater infiltration, the installation process ensures uniform liner quality.

- Cement Grout Application & Long System Lifespan: Cement grout is injected between the host pipe and the Nordiloc S liner and the composite installation method provides a durable, long-lasting system.

|

Ensures full structural strength and resistance to groundwater over 10 meters

INSTALLATION

The strong and flexible liner is folded and pulled into the existing pipe. Special tapes help it keep its shape during installation. It´s then inflated with air or by fluid pressure, without bonding to the old pipe. Unlike CIPP, no curing is needed. Keeping drinking-water networks functional is elemental to maintaining our standard of living and is an important responsibility of water suppliers. Leaky pipelines result in wasted resources and can cause serious damage to infrastructure.

|

| |

| |

| |

| TRENCHLESS REHABILITATIONWe offer trenchless pipe rehabilitation for all kind of piping systems, including sewage, water, gas, undustrial pipes. | | VAST RANGEOur solutions include Cured-in-Place-Pipe (CIPP), Pull-In-Place-Pipe (PIPP) and Close-Fit-Pipe. |

| HIGH PERFORMANCEThese technologies provide the highest performance and most effective solution covering all diameters and pressure range. |

|

MAIN PRODUCTS

|

|

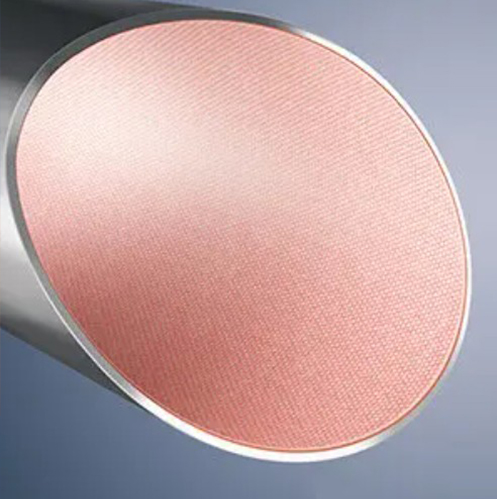

| TUBETEXApplications: Water, Gas, Industry Diameter: 800-1200 mm / 3" - 48" Material: Seamless woven fabric Polyester yarn Coating: PE, TPU or TPC Classification ISO 11295: C - relies on addition |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

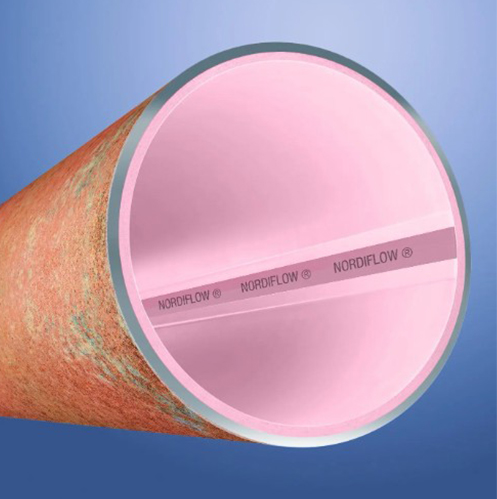

| NORDIFLOWApplications: Water, Gas, Industry, Oil, Heat pipesDiameter: 150-1400 mm / 6" - 56" Material: Glass fibre reinforced felt Coating: PE, PP or HT Pressure rate: A & B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

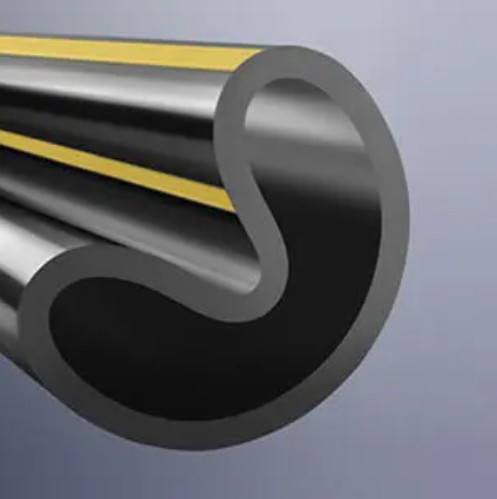

| CLOSE-FITApplications: Water, Gas, Industry Diameter: 200-400mm / 8" - 16" Material: PE100 Coating: PE, PP or HT Classification ISO 11295: A & B |

|

|

|

|

|

|

|

|

|

|

|

|

|

WHY US? Our many years of experience in pipe rehabilitation and innovative technologies enable us an optimal support for our customers. We have brought many construction companies to break into the market of NoDig pipe rehabilitation over the last decades. | |